Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

ネオジム鉄ボロン (NdFeB) 磁石は、希土類磁石としても知られ、音響を含むさまざまな業界で広く使用されています。これらは、その優れた磁気特性と高い保磁力で知られています。 NdFeB 磁石は、小型で強力な磁場を提供するため、スペースが限られている音響用途での使用に最適です。この記事では、NdFeB 磁石の形状、サイズ、公差、性能、コーティング要件、ベトナムとインドの市場展望など、音響分野における NdFeB 磁石の応用の概要を説明します。さらに、Zhejiang Zhongke Magnetic Industry Co., Ltd.の製造上の利点を分析します

+86-15857968349

+86-15857968349

音響用途における NdFeB 磁石:

音響業界では、スピーカー、マイク、補聴器、ヘッドフォンなどのさまざまな用途に NdFeB 磁石が使用されています。 NdFeB磁石はオーディオ機器や楽器にも使用されています。高磁場強度や高保磁力などのユニークな特性により、多くの音響用途に最適です。

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

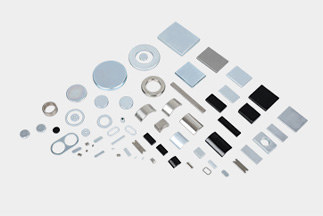

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

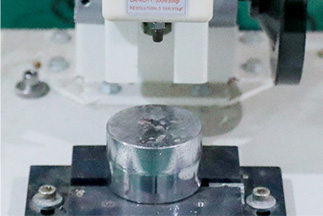

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

形状、サイズ、公差:

音響用途に使用される NdFeB 磁石は、さまざまな要件に合わせてさまざまな形状とサイズで入手できます。最もよく使われる形状は直径3mm~40mm、厚さ1mm~30mmの円筒形です。ヘッドフォンに使用される NdFeB 磁石は通常、直径が 10 mm 未満と小さいです。一方、スピーカーでは通常、直径 10mm ~ 40mm のより大きな磁石が使用されます。マイクに使用される NdFeB 磁石は通常、スピーカーに使用される磁石よりも小さく、通常は直径が 3 mm 以下です。音響用途向けの NdFeB 磁石には、特定の要件を満たすために高い公差レベルが必要であり、公差レベルの範囲は /-0.05mm ~ /-0.1mm です。

パフォーマンス:

音響用途に使用される NdFeB 磁石には、優れた磁気特性が求められます。これらには、高い最大エネルギー積、高い保磁力、および高い磁束密度が含まれます。音響用途で使用される NdFeB 磁石の最大エネルギー積は 32MGOe ~ 55MGOe の範囲です。保磁力は 11,000 Oe ~ 14,000 Oe の範囲です。磁束密度は12,000G~15,000Gの範囲です。

コーティング要件:

NdFeB 磁石は、特に湿気の多い環境にさらされた場合の腐食を防ぐためにコーティングされています。このコーティングは、取り扱いや設置中の損傷に対する保護層としても機能します。 NdFeB 磁石に使用される一般的なコーティング材料には、ニッケル、亜鉛、金、エポキシなどがあります。亜鉛とニッケルのコーティングは、低コストで高レベルの保護が可能なため、最も一般的に使用されています。

ベトナムとインドの市場展望:

ベトナムとインドのネオジム磁石市場は、長年にわたり着実な成長を遂げてきました。両国は音響産業において大きな潜在力を持っており、そのためこれらの市場では NdFeB 磁石の需要が増加しています。ベトナムでは、NdFeB 磁石の需要は自動車産業によって牽引されており、電気自動車、パワー ウィンドウ、モーターに使用されています。インド市場は、家庭用電化製品、航空宇宙産業、自動車産業における NdFeB 磁石の用途の増加により成長を遂げています。

浙江中科磁業有限公司の製造上の利点:

Zhejiang Zhongke Magnetic Industry Co., Ltd. は、中国の大手 NdFeB 磁石メーカーです。同社は、音響を含むさまざまな業界向けの NdFeB 磁石の製造において豊富な経験を持っています。同社の製造工場には、高度な生産設備、試験機、検査ステーションなどの最新の設備が備えられています。同社は高度な技術を使用して、高レベルの精度と一貫性を備えた高品質の NdFeB 磁石を製造しています。同社は、製品の品質の継続的な向上を保証する厳格な品質管理システムを開発しました。浙江中科磁業有限公司が生産する高品質NdFeB磁石は、世界中のお客様から信頼を得ています。

NdFeB 磁石は、スピーカー、マイク、補聴器、ヘッドフォンなど、音響業界で幅広い用途に使用されています。高い磁場強度や高い保磁力などのユニークな特性により、音響用途での使用に最適です。音響分野で使用される NdFeB 磁石にはさまざまな形状、サイズ、公差レベルがあり、ベトナムとインドでの市場の見通しは有望です。 Zhejiang Zhongke Magnetic Industry Co., Ltd. は、高度な技術と製造能力を備え、音響業界やその他の分野の顧客のニーズを満たす高品質の NdFeB 磁石を提供しています。

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.